Engineering

Engineering the future of food, feed & proteins

What We Do

At ENLECO, we develop tailored engineering solutions for machines and full-scale processing plants in the food, feed and protein industries. From concept to commissioning, we support you across the full process – from raw material intake to final packaging – covering all core engineering disciplines.

From Idea to Solution

Every project is different – whether it’s about developing individual machines or engineering entire processing plants. At ENLECO, we’re familiar with both worlds and bring the technical expertise to see the bigger picture. We approach engineering with the entire value chain in mind: from the first concept idea through mechanical, electrical and process design to implementation support. A new production line, a retrofit or an expansion – we step in where you need us.

- Feasibility studies & Concept development

- Development of Machinery, Systems & Processes

- Planning and Execution of New Plants, Retrofits ans Expansions

- Support during Assembly, Testing & Commissioning

- Service Support & Life Cycle Management

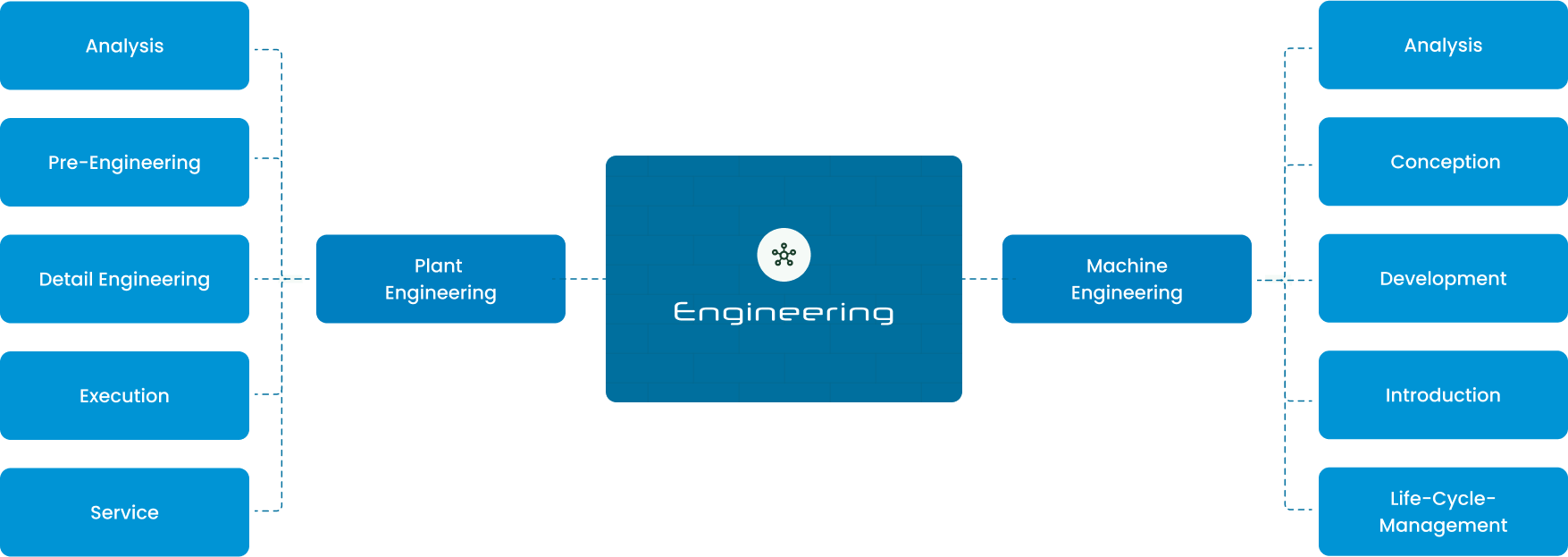

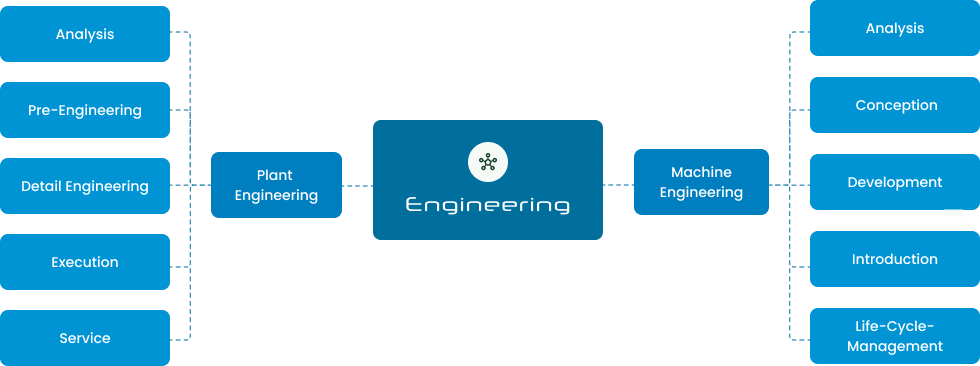

Two Processes – One Goal: Smart Solutions

Whether it’s a full-scale plant or an individual machine – we work with you along two clearly defined engineering paths. Our plant engineering is designed to turn complex production flows into working plant solutions – from raw material intake to final packaging. Machine engineering focuses on developing technical functions, modules and assemblies. Both follow a structured logic – from requirements to implementation.

Engineering

Each of these sectors has its own specific requirements – and that’s exactly what we’re specialized in.

Mechanical

We take care of mechanical design for machines, assemblies and components. This includes layout planning and integration into plant environments, always with a focus on functionality, durability and manufacturability.

Electrical

We plan and implement electrical systems that ensure reliable operation and safety – from power distribution and circuit design to wiring, protective devices and field-level integration. Our scope also includes cabinet planning, component specification and coordination with other disciplines.

Automation/Software

We develop PLC-based control systems and implement HMI and SCADA for operation and monitoring. This includes signal logic, interface integration and coordination with mechanical and electrical systems. When standard solutions fall short, we create customized software tailored to your needs.

Process Technology

We develop product and media flows, thermal systems and process logic – always tailored to your product and production requirements. This includes the design of flow diagrams, media networks and functional sequences to ensure smooth integration into your overall process.

Service

We take over and support installation and commissioning on site – ensuring a smooth transition from planning to operation. Our service includes assembly, supervision, technical coordination and ongoing support throughout the system lifecycle.

ENLECO Advantage

With ENLECO you get not only support, but structure, technical understanding and real implementation power on board. We make your project our own – and bring it to success with you.

What our customers say

If you have any questions, please feel free to contact us.

Thank you!

We will contact you soon.